Bag-in-box filling instructions

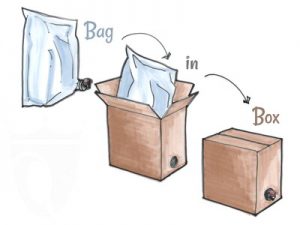

ATTENTION: the name bag-in-box (Romanian: bag-in-box) means that the product is composed of 2 parts: bag and box! The box is not "packaging for sale" as is the case for transporting 6/12 glass bottles. The box from the bag-in-box component is the structure of the product's resistance to external pressures, stings or scratches, ensuring the reliability of the inner bag and protecting it from the sun's rays.

TECHNOLOGY OF PASTEURIZED JUICE PRODUCTION

After obtaining the juice by pressing, it must be pasteurized. If we do not pasteurize it, due to the existing fructose, it will ferment. That is, fructose (which gives the sweet taste of juice) is transformed by yeast into alcohol, with the release of carbon dioxide. In order for the juice not to ferment, the yeasts had to be removed. This elimination of the yeasts is done by heating the juice to over 80 degrees Celsius, preferably over 82 degrees Celsius. This process of heating the juice is called PASTEURIZATION (after the great French biologist Louis Pasteur who discovered this process and applied it widely for disinfection and sterilization). Pasteurization will be done with the help of the PASTEURIZER, which is an equipment that has an automation to keep the juice at this high temperature. In this equipment, the juice enters cold and at the exit has a temperature of 82-84 degrees Celsius. After pasteurization, the juice should be placed in the Bag-in-Box IMMEDIATELY. When the juice reaches the bag, it must have a temperature of over 78-80 degrees Celsius. Being hot, it sterilizes the bag on the inside. Do not put pasteurized and cooled juice!

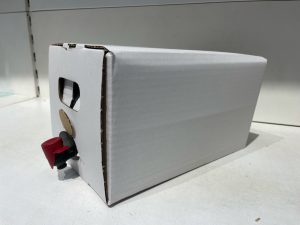

After that, the bag had to be placed to cool, carefully on a flat surface with the stopper up, on a single layer. Do not put bags on top of each other! After it has cooled to about 30 degrees Celsius (hand temperature), place it carefully in the box, avoiding that the edge of the box does not scratch the bag. The bag does not hold the stopper !!! Because the material around the plug is hot, there is a possibility that it will deform and the plug will come off. The bag must be put in the box, because the very name of the bag "Bag-in-Box”In translation means "Bag in the box." Failure to store the bag in the box leads to mechanical stresses of the bag which can lead to damage.

The bag manufacturer recommends testing a sample of 2-3 bags before using the bag-in-box.

Usage steps:

Step 1- empty bag

Step 2- remove the plug carefully so as not to damage the bag

Step 3-Fill the bag and put the stopper. Place (without overlapping several bags) until acclimatized to room temperature

Steps 4 and 5- carefully place in the box, with the stopper next to the cutout for the stopper (round shape)

Step 6- Close the box

Steps 7 and 8 (for the final consumer or for tests) - turn the box over, break the cutout for the stopper and remove the stopper

Step 9: Remove the food grade plastic stopper seal

Step 10: pour into the glass / cup / etc