Are you looking for a business opportunity with relatively low investment, fast depreciation and minimal effort ?

We present the Oranfresh natural juice juicer-dispenser. Product patented and manufactured entirely in Italy.

Are you active in the HoReCa field and do you want to offer your customers a healthy, natural and available product non-stop?

In this case, the Oranfresh OR range is perfect for you and your current or future business!

BENEFITS:

-Capacity of over 100 glasses facilitates the loading (depending on the traffic of the area where it is located) of maximum 1 time every 24 hours;

-Your work is a maximum of 5 minutes / loading (filling with fruit and emptying the basket of vegetable waste; possibly emptying the money drawer, if you have equipped this module);

-You can customize it with the image of your company and you can create a strong brand;

-It has a customizable 7 inch color display for easy customer interaction;

-The transparent glass with a view to the process of squeezing the fruits, is a guarantee of the natural product offered by the customers;

-The cleaning function with high pressure water jet, saves you from the need for daily washing;

-The footprint of less than 1 m2 facilitates installation in any location, making the perfect dispenser for airports, malls, train stations, parks, pedestrian areas, restaurants, hotels and any other place you could choose where pedestrian traffic is high. (A 'secret' tip is to install in DIY stores or markets, where the beverage area is poorly developed and competition is low, applying the BLUE OCEAN strategy);

-Energy consumption between 800 W and 1000 W (depending on the model) ensures an increased economy and care for the environment compared to Chinese alternatives (of questionable quality).

Role models

1) CITRUS JUICE JUICE-DISPENSER OR 130- The classic model of vending type orange juicer, with a capacity of 100-130 glasses (depending on the volume of the glass)

Available here: https://loredo.ro/ro/product/storcator-dispenser-suc-de-citrice-or-130/

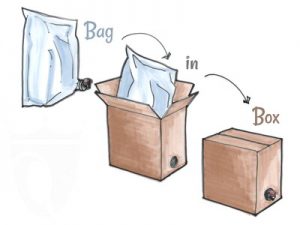

2) JUICE-DISPENSER OF ORANGES OR 130 MULTI-FRUIT-Juicer-Dispenser citrus juice + pasteurized juice addition tank.The filler tank can also be used for energy drinks, dietary supplements or coffee-based beverages.

Available here: https://loredo.ro/ro/product/storcator-dispenser-de-portocale-or-130-multi-fruct/

3) JUICER - ORANGE JUICE DISPENSER OR FILL UP- juicer - citrus juice dispenser with PET bottle packaging. Device designed for supermarkets and self-service areas.

Available here: https://loredo.ro/ro/product/storcator-dispenser-suc-de-portocale-or-fill-up/

4) APPLE JUICE OR APPLE JUICE DISPENSER - Apple juice dispenser. Unique patent for squeezing apples.

Available here: https://loredo.ro/ro/product/storcator-dispenser-suc-de-mere-or-apple-juice/

5) SPRAYER - ORANGE DISPENSER IN GLASS WITH INSULATING FOIL OR TAKEAWAY

Available here: https://loredo.ro/ro/product/storcator-dispenser-de-portocale-in-pahare-cu-folie-izolatoare-or-takeaway/

Optional equipment

- payment method with banknotes;

- coin payment mode;

- card, telephone, contactless and QR payment mode;

- advanced telemetry mode (sales monitoring and remote diagnosis);

- ozone cleaning system with UV lamp;

- can be ordered with the customer's logo or design